Toppings are subject to the same general industry recommendations for hot- and cold-weather concreting practices as any other concrete. Proper planning and execution is essential for minimizing the negative effects of weather extremes on topping placement, consolidation, finishing, curing, and strength development.

When planning around the effects of ambient conditions on topping construction, a key factor to consider is the mass of the existing slab. In hot and cold weather extremes, the topping and base slabs will normally be at different temperatures when placed but will come to a thermal equilibrium during curing. Typically, the base slab accounts for the bulk of the composite slab (bonded or unbonded) so conditioning of the base slab prior to construction cannot be overlooked.

Thinner toppings may be more susceptible to temperature-related issues. A cold base slab can cause finishing problems due to delayed set, retarded strength gain, or even freezing of the topping if not properly conditioned. A hot base slab can lead to rapid stiffening that negatively affects workability, consolidation, finishing, and bond.

Industry recommendations for dealing with hot and cold weather are well documented; however, concrete placements are also exposed to other weather-related risks that the industry is nearly silent on, such as rain. Weather is difficult to predict, and placements often occur when there is a chance of rain to meet project schedule demands. Timing, duration, and intensity of a rainstorm are all important variables that can affect the success of a placement.

Exposure to Rain During Placement

Under most circumstances, concrete placements exposed to rain will not be damaged if excess rainwater is removed prior to finishing. According to the Guide to Concrete Flatwork Finishes published by Cement Concrete & Aggregates Australia, if the concrete surface appears wet (similar to bleeding) the rainwater will need to be removed to allow continuation of finishing. The common concern is that rain may increase the water-cement ratio of the placement resulting in lower strength, higher shrinkage, and a weaker surface. This may be true if the water cannot or is not removed prior to finishing; however, contractors have shown that this is not the case when precautions are taken to remove excess water. The most common precautions are to either cover the concrete with plastic or allow exposure to rain and remove the excess water prior to finishing.

If possible, the placement can be covered with plastic to minimize contact with rain. While this is good practice, the application of the plastic may be difficult or impossible if laborers cannot walk on the surface, the sheets are not wide enough to cover the entire width of the placement, or reinforcement or other penetrations protrude through the topping. Some contractors also caution against the use of plastic since it retains heat and can cause the surface to set faster. Reducing the window of finishability under these circumstances can be undesirable because additional time may be needed to remove water and complete the finishing operations.

Many contractors leave the surface uncovered and allow the exposure to rain. Similar to bleed water, rainwater will not be absorbed by the slab, but it must evaporate or be removed prior to finishing. Some contractors like to drag a long garden hose over the slab to remove excess water while others prefer to use squeegees or short lengths of rigid foam insulation to guide water off the slab. Some surface paste may be removed with the excess water, but this is generally not an issue since additional finishing typically brings more paste to the surface.

Contractors should never broadcast dry cement over the surface to help absorb excess rainwater. While the cement may react with the excess rainwater the resulting paste may not integrate into the slab surface. This leads to a poor-quality surface that is often prone to flaking and delamination.

Hot Weather

Under hot weather conditions, emphasis is placed on managing concrete setting times and minimizing moisture loss from the placement. The simplest way to summarize hot weather recommendations for topping construction is to work in stages (pre-placement, placement, and post-placement).

Hot weather considerations in the pre-placement stage include construction planning, concrete mixture design, and base slab conditioning. Concrete topping mixtures designed with a low bleed rate are particularly susceptible to common hot weather issues such as plastic shrinkage, crusting, and inconsistent setting time. These mixtures generally have a low water-cementitious materials ratio (w/cm) and high fines content from aggregate and fibers. Using a well-graded aggregate with the largest top size possible for the application is always advisable. This will improve water demand and workability for a given water content.

Conditioning of the base slab is one of the most important considerations when placing toppings in hot weather. Conditioning will vary depending on the topping design. Bonded toppings benefit from both temperature and moisture conditioning while only temperature conditions would be necessary to consider for unbonded slabs.

Base slab moisture conditioning for bonded toppings reduces moisture loss from the topping and can help prolong the setting time of the topping mixture by cooling the base slab. There is no standard procedure for conditioning a base slab and no standard test method for evaluating the surface moisture level of a base slab ready to receive a topping. Contractors surveyed about their base-slab hot-weather preparation reported a range of successful conditioning methods.

Some contractors wet the surface with a garden hose while others like to use a pressure washer to help clean and force water into surface pores. After wetting the surface, contractors report a wide variation in soaking or conditioning times. Some contractors that use power washers proceed with topping placement immediately after wetting and removal of excess water from the surface. Depending on ambient drying conditions, others will wet the surface more than once or cover the surface with plastic and condition it for between two and 24 hours prior to removing excess water and placing the topping mixture.

The temperature of the base slab may also need conditioning if it is substantially warmer than the topping mix. A hot base slab can negatively impact the topping mix by reducing its workability, increasing water demand, and accelerating setting time. Temperature conditioning can be difficult based on the mass of the existing slab. Unless the slab is enclosed or shaded, there are few alternatives for reducing base slab temperature. Contractors in the southern U.S. prefer wetting down the surface with cool water or placing the topping mix at night or both. Contractors surveyed did not limit topping placements based on substrate temperature; most preferred night placements and moisture conditioning, based on experience. In a study of bonded pavement overlays in Texas, researchers reported base slab temperatures of 140 F or higher during summer in direct sunlight and recommended avoiding topping placements when substrate temperatures were more than 125 F.

Hot weather considerations in the placement stage include managing concrete delivery temperatures and moisture loss from the topping slab during the finishing process. The same procedures used to manage concrete temperature for slabs can be followed for toppings.

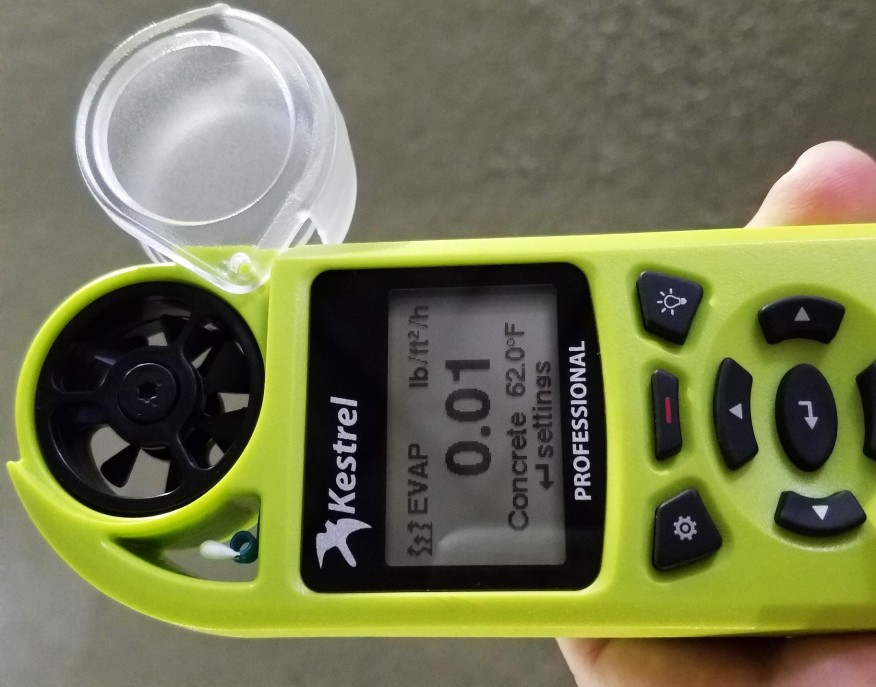

In addition, moisture loss from a concrete topping should be monitored and minimized. Rather than using online evaporation-rate estimators or nearby weather station data to calculate the evaporation rate, a handheld weather station should be positioned at a height of about 20 inches above the slab surface. Equipment is available that can measure the ambient air temperature and relative humidity as well as the wind speed. These devices only need to have the concrete temperature entered to automatically calculate the evaporation rate. When the evaporation rate exceeds 0.15 to 0.2 lb/sf/hr, action should be taken to decrease the evaporation rate from the topping surface.

Cold Weather

Under cold weather conditions, emphasis is placed on preventing early age freezing and managing ambient temperatures during curing to promote strength development. Managing the base slab temperature during placement and curing of the topping slab may be the most challenging aspect related to cold weather concreting.

The base slab will likely have a greater mass than the topping slab. As a result, the temperature of the base slab will have a significant impact on the topping slab placement. Topping slabs should never be placed on a frozen base slab since the temperature of the base slab will draw heat away from the fresh topping mix.

Industry recommendations are that the base slab should be maintained at a temperature of at least 40 F during placement and curing of the topping to promote hydration, strength development, and avoid early-age freezing. Cooler base slabs may retard the set of the topping mix, prolonging bleed time and finishing activities. This may also make the topping more susceptible to other finishing issues such as plastic shrinkage and surface crusting. Whenever possible, we recommend heating the base slab to prevent freezing and provide acceptable curing conditions.

Cold weather topping mixtures can be designed to help offset the effects of ambient and base slab temperature on setting time. Replace slower reacting supplementary cementitious materials with straight cement, use Type III cement, and use accelerating admixtures (consider increasing dosage as the placement progresses to maintain an even setting time).

Moisture conditioning the prepared base prior to placement can be challenging in cold weather. Pre-wetting the base slab is not recommended if freezing is expected. Most toppings, however, are constructed on existing slabs where the building is constructed and enclosed. Therefore, adding heat to the area where the topping will be placed is usually less of a challenge than it is during initial construction of the superstructure and base slab.

As with pre-wetting of the base, moist curing should also be avoided if freezing is expected. However, thin bonded toppings are particularly sensitive to early drying while the bond strength is developing. If the bonded topping dries and shrinks prior to developing adequate bond strength to the base, shear forces can cause the topping to delaminate from the base. Once delamination occurs at an early age, the topping will not reestablish bond to the substrate. Therefore, preventing early drying is an important factor in the construction of bonded toppings.